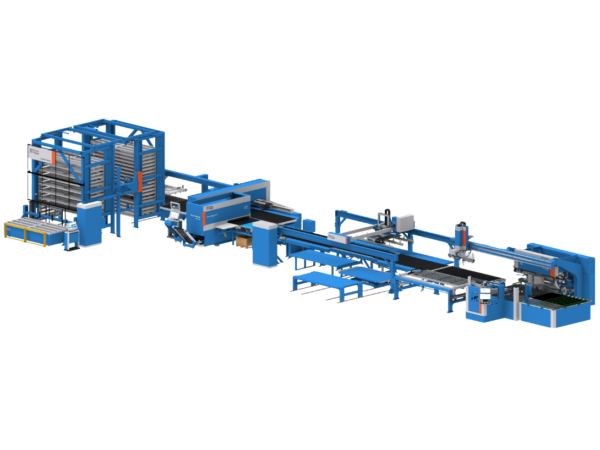

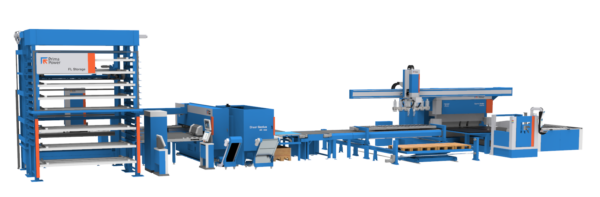

Prima Power PSBB line processes blank sheets into ready-bent, high-quality components automatically. PSBB stands for Punching + Shearing + Buffering + Bending.

Material flow can be arranged in flexible ways: to transfer parts directly to automatic bending, to balance the different time requirements of bending and punching/shearing, to exit material from the system and to bring new material into it. The flexible and versatile buffering function ensures that optimum operation in terms of manufacturing cost and throughput time can always be chosen, whatever the manufacturing task at hand. Flexible buffering ensures optimal operation of integrated machines.

The productivity offered by this concept derives from integration of:

- Versatile servo-electric punching

- Integrated servo-electric shearing

- Servo-electric bending

- Automatic, flexible material flow and

- Sophisticated software

Features

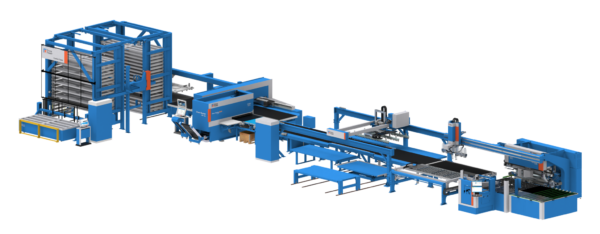

- Automatic information flow from programming to production reporting.

- An integrated production system, reducing the whole fabrication process into a single one.

- Automatic manufacturing stages.

- Automatic material handling including intelligent buffering.

- Minimum manufacturing time, maximum production time.

- Optimal value stream from raw material to ready-made components.

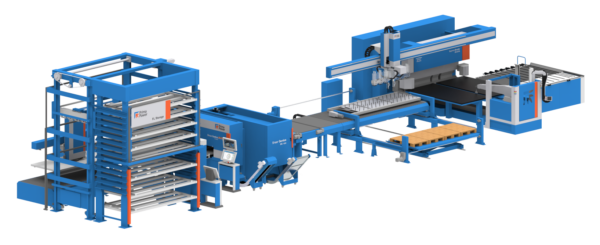

FLEXIBLE WAYS TO PRODUCE

- Direct material flow from a punching-shearing cell to the bending cell.

- Simultaneous stacking on tables/wagons and retrieval of components from tables/wagons to the bending cell.

- Use of the whole stacking area in unattended operation.

Reviews

There are no reviews yet.