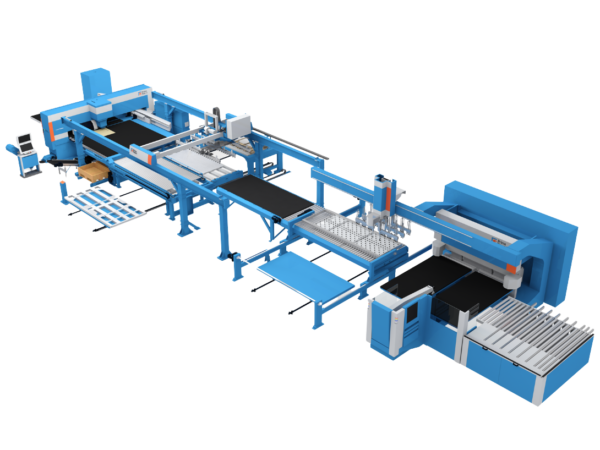

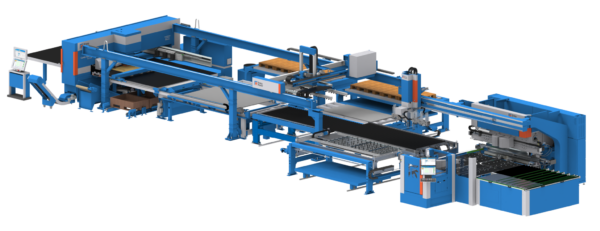

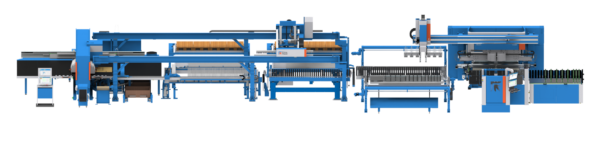

LPBB stands for Laser cutting + Punching + Buffering + Bending. The outstanding productivity offered by the LPBB flexible manufacturing system results from Prima Power modular technology and intelligent material flow management.

The compact LPBB sheet metal manufacturing system processes blank sheets into ready-bent, high-quality components automatically. The manufacturing system integrates punching, laser cutting, bending and intelligent part handling.

Features

LPBB integrates punching, laser cutting, intelligent part handling and high-quality bending. Very fast reaction times are expected in modern production. The machine needs to be flexible and extremely fast for a quick response to production orders, often for very small quantities.

There may be a rush order, or a test series to prove delivery capacity; here the laser is often the answer. Again, in longer series punching adds manufacturing speed and cost efficiency, allowing e.g. versatile forming and provides competitiveness unmatched by individual laser or punching machines.

The productivity offered by this concept derives from the integration of:

- Versatile servo-electric punching

- Modern laser cutting

- Servo-electric bending

- Automatic, flexible material flow and

- Sophisticated software

Reviews

There are no reviews yet.